The creation of the aluminum shaft is the most time consuming component of the ewespinner because it has to be manually created on a metal lathe by hand.

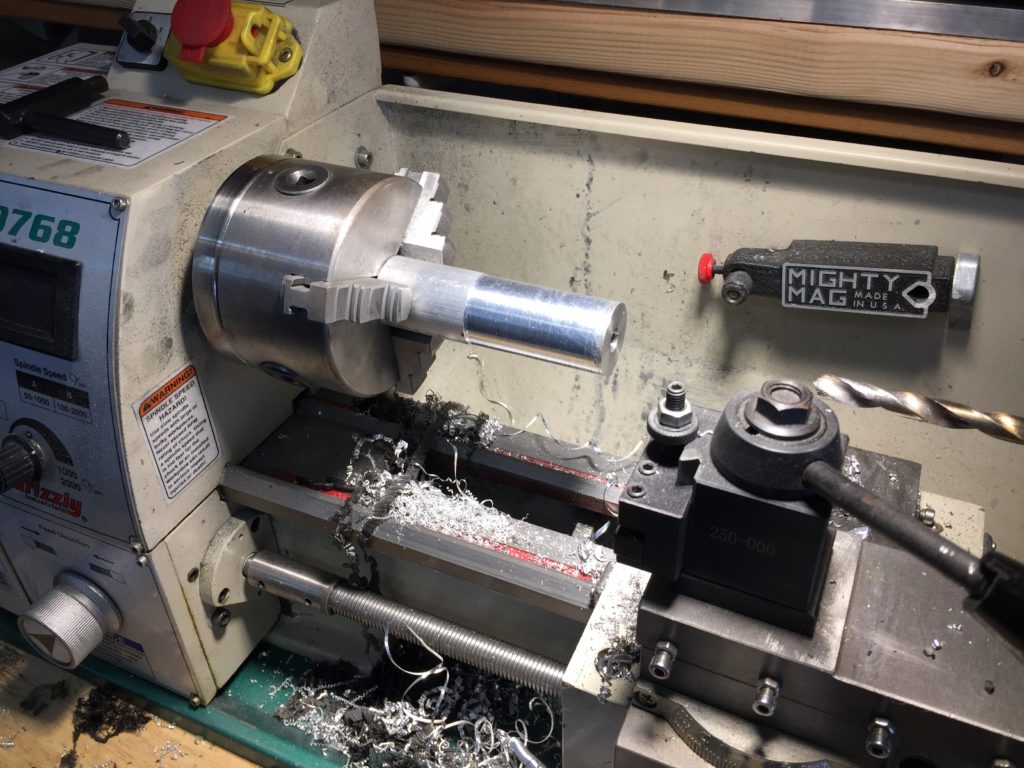

Drilling the orifice into the shaft (above).

Reducing the diameter of the stock aluminum bar to the necessary diameter and creating the pulley where the drive band will wrap around (above).

Reducing the diameter of the stock aluminum bar to the necessary diameter and creating the pulley where the drive band will wrap around (above).

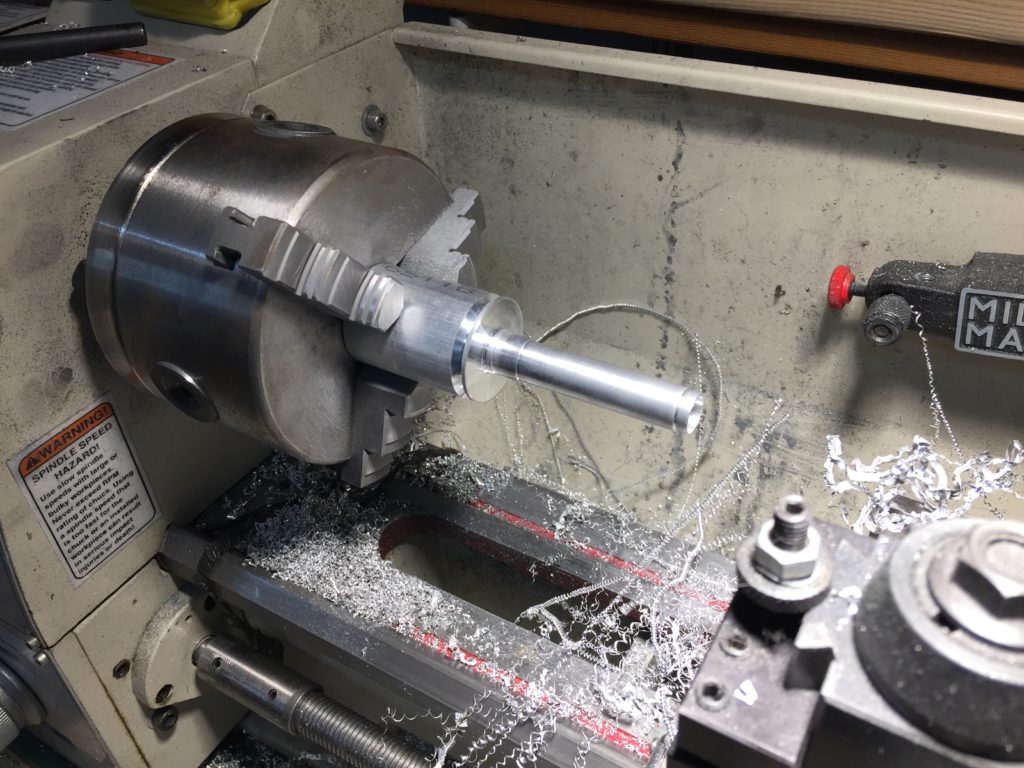

Reducing the diameter to fit the flyer and create the angled nose where the bobbin’s bearing will make contact (above).

The almost completed shaft. The only thing remaining is the hole where the yarn will pass through. This hole will be created on a drill press using a special mounting bracket so it doesn’t move around while drilling (above).