Never new how much thought had to go into the design of a bobbin. Things to considered when designing a bobbin:

- Will the bobbin’s hole diameter fit on a lazy cate’s post.

- Lazy cate tension system. How to provide tension on the bobbin so it won’t de-spool when the spinner slows or comes to a stop.

- Total weight effects maximum RPM (Revolutions Per Minute).

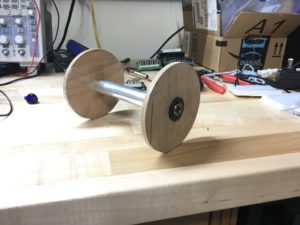

Initially, the bobbins used wood hubs with an aluminum shaft, but there were draw backs when using wood:

- The wood would warp depending on how much moisture was in the air. This caused the bobbin to become unbalanced and resulted in vibration in the ewespinner at different speeds (RPM).

- If accidentally dropped, the wood ends can brake or chip.

- The faster the wooden hubs spin, the centrifugal forces will increase. If there are any flaws in the wood, the disc could break.

- Wood can be heavy, resulting in an increase load on the motors when turning the bobbin, this, in turn, resulted in additional amps and less top end RPM speed.

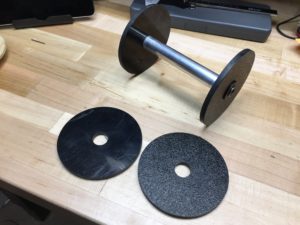

Advantages of ABS plastic:

- Very strong: will not brake or chip when dropped.

- Will not warp.

- Long lasting.

- I can make the diameter discs larger because of the variable dual-drive system. Increased weight will reduce maximum RPM, but will allow more yarn to be spooled onto the bobbin.

Disadvantages:

The shiny side is scratched during the creation process.